great planes magnetic building board

|

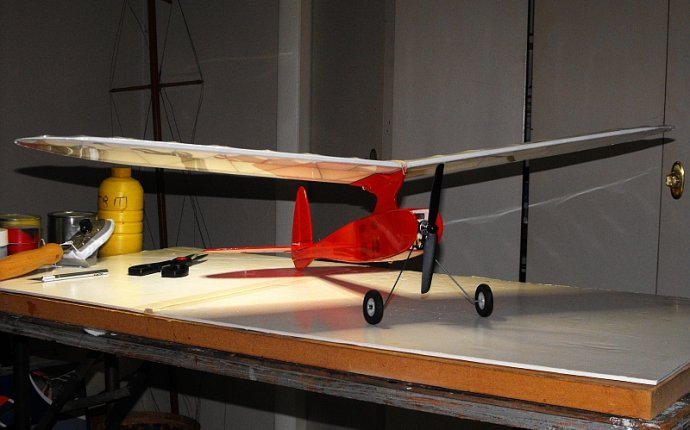

Build on a good board. A good building board is common thin steel sheet that can be obtained from a metal dealer in your area. I recently visited a recycling center looking for tempered aluminum plate and found steel boards at really low prices. The prices were much less than I paid for my board. I wish I had known (the aluminum was much less expensive than through the hobby industry as well). Look for Metal, Scrap Metal or Recycling in the Yellow Pages. Call around to let them know what you're looking for and get directions. My main board is 24" x 60". I can build larger models on this board and have extra room to place fixtures and on-the-fly magnetic jigs. It's not gridded and I still haven't gotten around to scribing one so I draw lines with a pencil and remove them with solvent when I'm done. I used to recommend against buying galvanized metal because I thought all galvanized metal had that swirly finish to it. I've since learned that's not true. Some galvanized metal is plain gray steel and looks very similar to my larger board shown below. If that's the case then galvanized is a great way to go. It's inexpensive and won't rust. After being flat, I consider low maintenance the next most important quality. I now own several tools that have cast-iron tables and those things soak up a lot of my time in the shop. It doesn't matter how often I wax them or what sort of "guaranteed" coating I apply to them. If I leave them unattended for a month or longer they will have rust on them. I'd gladly trade them in for thick aluminum plate tables. I don't care how stable cast iron is supposed to be. I'm over cleaning off rust and waxing all the time. The point is you want a board that won't rust. Good Boards are

Important: Some steels do not accept magnets. Take a magnet or two with you when you pick out your board to test before you buy. Uncoated boards need to be to protected from rust — climate control, paint or frequent wax applications. My board was cut from a piece having an undercoat treatment to prepare it for paint and that's how I use it. I wax it with automotive wax before I start a new project to help glue and tape release more easily. It doesn't rust so I don't have to look after it all the time when it's not in use. Sheet steel will conform to any acceptably flat surface that can support the board and the structure being built. Undamaged sheet flattens under its own weight and does not require hardware, weight, adhesive or clamps. Both of my boards are thin and I like them that way. I'm not sure of the gauge but they're 20 or 22 gauge. They are slightly less than 1/16" (1.6 mm) thickness. The boards are light enough that I can remove them easily when they aren't needed because they are mostly in the way on the bench when I'm not using them. Thick steel sheet or plate is heavy, difficult to handle and usually a poor choice unless you are building a half-ton bench having a permanent steel top. If a thicker top is wavy it will probably not lay flat and will need to be milled. I don't recommend you use a thick top unless you know something about metal working and understand what it will take to turn the plate into a flat bench top. I recently spoke to a person who wanted to have a fair size piece of steel plate fly-cut and powder coated. The quote he received was several thousand dollars not including the bench he would be building under the steel. The board dimension should be approximately one foot longer and one foot wider (6" on all sides) than the largest models you build to allow room around the model for magnetic fixturing. Ask them to cut it to finished size and you should walk out smiling. If the board has burrs around the edges the first thing you should do is remove them. I use a file and finish with medium sandpaper. Round over all four corners so they aren't snagging things like your clothes, shop towels, covering, etc. About 1/8" radius is usually good. Do not buy a damaged boardIf the dealer wants to give you a damaged board for free then graciously accept it and while you're there buy the undamaged board you still need. A damaged board can be used as a storage board which is the best... |